ADG Solutions, reclaim and recycling equipment experts to the plastics industry for over 25 years, is the exclusive distributor in North America of Break Machinery Srl (Grantorto, Italy). To obtain high quality polymers in recycling processes, filtration is one of the most important steps. Break Machinery has developed the DUO double-filter system, which allows high productivity while guaranteeing a high-quality end product.

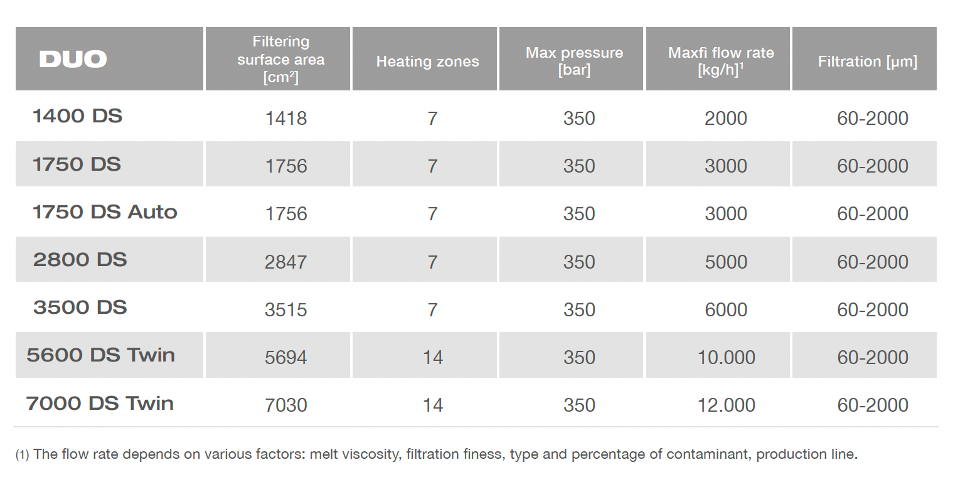

Break Machinery offers a complete range of automatic and efficient filtration equipment that now covers applications from 1000 lbs/hr to 24,000 lbs/hr. The DUO self-cleaning double filter systems boasts high productivity with the ability to produce high-quality melt from contaminated sources. This new innovative design is suitable for fine or course filtration and can filter heavy levels of contaminants with a new double screen design.

The geometry of the scraper disc and the innovative contamination discharge system allow contamination to be removed in a rapid and controlled manner and reduce the amount of waste.

DUO is equipped, as its name explains, with two perforated discs (‘breakers’), thus increasing the filtering area and production volume. The scraper disc, placed between the two filters, has blades on both sides and rotates to remove contamination from both surfaces. In addition, its geometry prevents filtered contaminants from re-entering the melt. The filter surfaces are constantly cleaned, so that they can be used for longer periods than with conventional systems.

The use of two filters makes it possible to reduce the size of the filtration chamber and to have large filtering surfaces, while the system’s operating principle allows it to work in continuous mode and at constant pressure. Manufactured using high quality alloy steel and adopting anti-wear treatments in the most stressed parts, DUO is designed to guarantee high resistance to line pressures (up to 350 bar).

The special geometry of the six-blade rotating scraper disc ensures excellent cleaning even at low rotation speeds. Impurities are discharged by means of a single screw capable of conveying them from both filter surfaces. The system is designed to filter various types of plastic materials with high percentages of impurities (up to 15% by weight) and handle different contaminants such as paper, wood, aluminum, copper, etc.

The adjustability of the speed of the discharge screw allows even the most contaminated materials to be handled, while maintenance operations and replacement of filters and blades can be carried out without dismantling machine parts. This innovative design reduces cleaning and replacement times for both the filter and blades and significantly reduces the operator time.

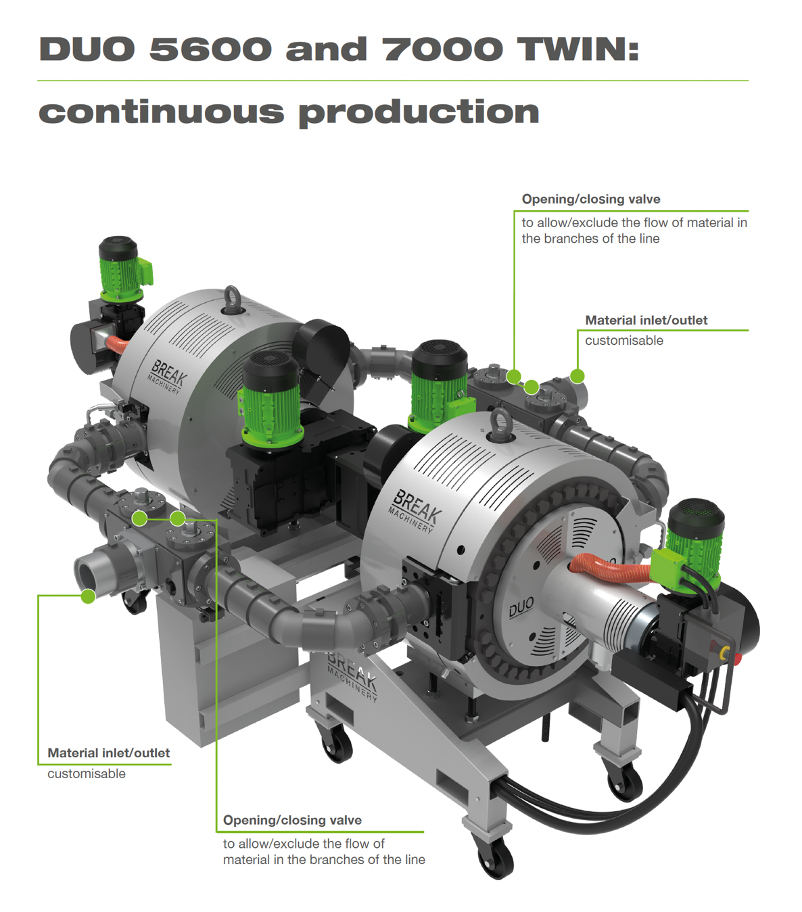

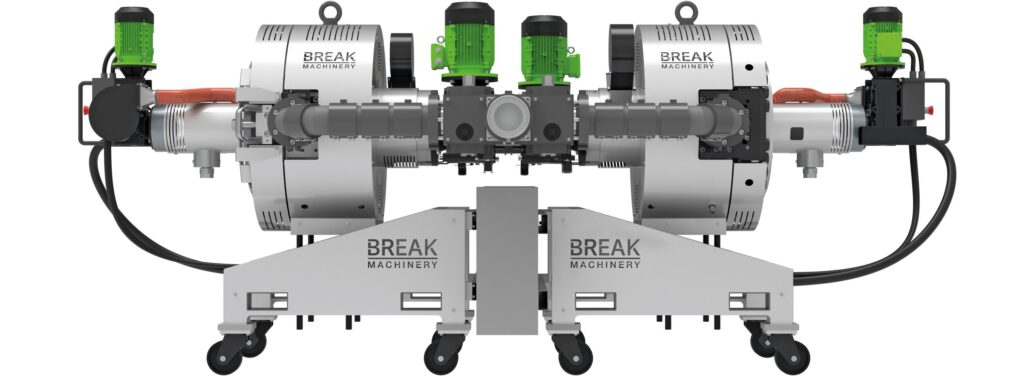

The complete DUO line now includes NEW models such as the 5600 and 7000 Twin:

The NEW DUO 5600 and 7000 Twin consists of two DUO, screen changers, of the same

size, running in parallel. When it becomes necessary to change the screen in the first machine, the flow of that branch of the line is stopped, and production remains active only on the other branch, connected to the second screen changer. In this way, production is not interrupted and the screen can be changed, without having to stop the line. The same process is then carried out for changing the screen in the second machine.

“We are continually looking to find the best equipment solutions to enhance our portfolio we provide to our customers,” says Sandy Guthrie, ADG President. “Taking the best quality machinery and marrying that with our advanced industry knowledge allows us to help our customers transform plastic scrap into high-value raw material.”