Feed Screws and Barrels

Pushing the Limits of Extrusion

Find the correct feed screw design for maximum quality and production.

ADG Solutions feed screws and barrels – new and rebuilt

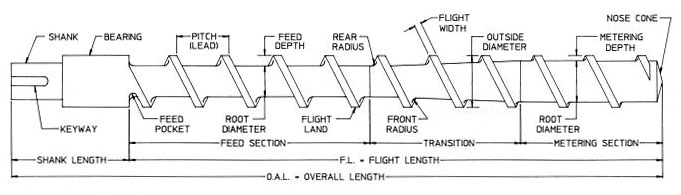

Selecting the right extrusion feed screw design for your process is critically important to optimizing melt conditions and maximizing your material properties. Plastic materials have broad variations in viscosity, melting points, volatiles, densities, moisture, sensitivity to shear, abrasive contaminants, etc. All of these variables, alone or in combination present significant barriers to maintaining homogeneity, melt consistency and output.

Plastics industry leader ADG Solutions can help you choose the optimal extrusion screw design for your process. From single-stage general purpose to two-stage barrier designs to double vented, with a host of mixer technologies and wear-resistant alloys, we have what you need to maximize your process. We have everything from low work to high work screw designs that work to keep your resins in proper condition.

Services

Feed Screws

- Custom design feed screws

- Utilize our expertise to solve problems and help develop new products/processes. These screws are specifically designed to the customer’s process.

- We have a full laboratory for screw evaluation and would be pleased to work with you and your process.

- General feed screws

- Uncomplicated designs for Nylon, PVC, high temp and GP profiles. These are typically designs that are process proven.

- Customer-supplied feed screws

- Feed screws manufactured to your design and supplied drawing.

- Feed screw modifications

- Special tips, end-caps and die adapters.

Barrels

- All sizes for extrusion with bimetallic liners

- Digital ID inspection of your barrel to determine wear and useful life

- Laser borescope inspections and setup available

Rebuilds

- Complete feed screw resurfacing, repair, re-cutting and modifying

Capabilities

Feed Screws

- Feed screws are available in diameters from ¾ ” to 12″ and lengths to 50 feet. Single or two-stage

- Common materials are 4140, 4340, Nitralloy 135m, 300 and 400 series Stainless Steel, 17-4PH and 15-5PH, CPM-10V, Hastelloy, Duranickel and Incoloy

- Hard facings range from flame hardened to Tungsten Carbide alloys. Standards are Colmonoy 56 and 83 and Stellite

- Available coatings are Chrome, Electroless Nickel, UCAR and other specialty coatings

Please wait while flipbook is loading. For more related info, FAQs and issues please refer to DearFlip WordPress Flipbook Plugin Help documentation.

Mixers

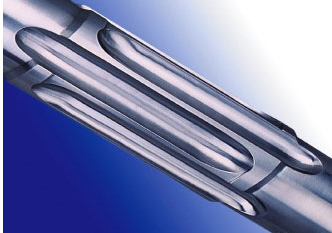

- Straight Maddock (Dispersive)

- Spiral Maddock (Dispersive)

- Distributive Mixer (MDM)

- Pins

- Blisters (fluted)

- Saxton

- Dulmage

Design

- ADG Solutions maintains an extremely large and comprehensive library of designs for screws. We also can design for specific materials/processes.