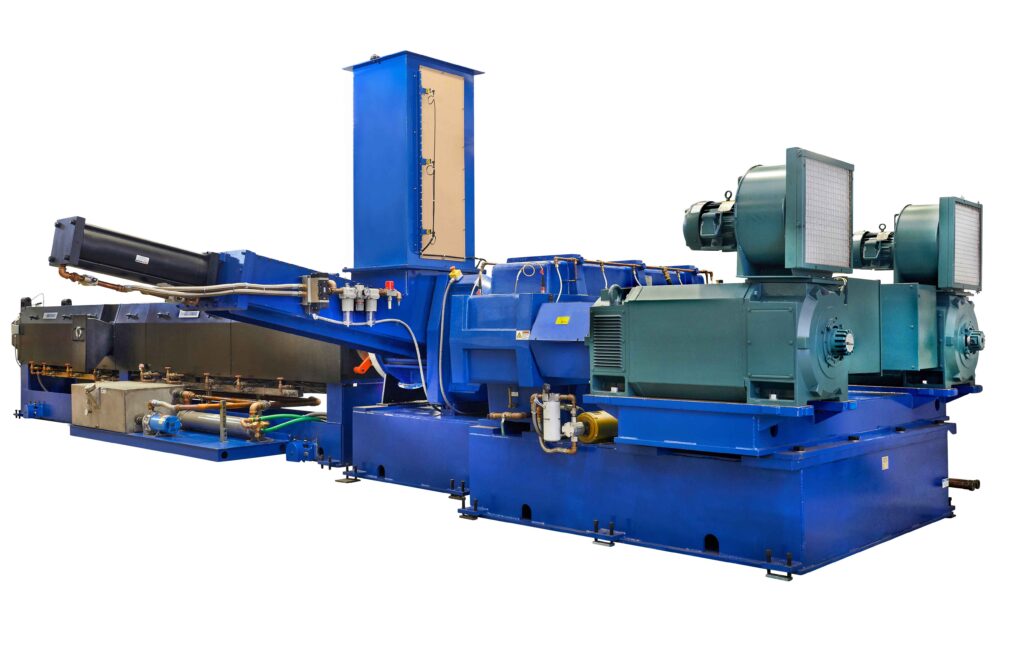

Davis-Standard Basic Features

Davis-Standard Extruders

Configured for the job, today and tomorrow!

Davis-Standard extruders are specially configured for the harsh demands of plastics recycling. All Davis-Standard extruders feature:

- Gearboxes with high horsepower rated, hardened and ground gears to ensure long life under heavy-duty demand. These gearboxes are built and serviced by Davis-Standard and designed only for plastics extrusion.

- Oversized, multi-chambered, flood-cooled feed throats to prevent melting of the solids or fines in the feed section and maximize the effective pumping of the screw.

- Single or multi-venting designs, which accommodate light or heavy degassing to eliminate bubbles and splay in your finished product.

- Advanced process controls, which enable visibility and control over every aspect of your process — from simple, discrete to complete PLCs with event logging, customized reports, SQC, historical trending, maintenance/troubleshooting, pressure set-up, and more.

ADG Solutions provides extensive knowledge and experience to properly size Davis-Standard extruders L/D to the feedstock and to process for the most efficient output. We design for your needs today and for years to come.

Materials forms processed can be:

- High bulk density scrap

- Low bulk density scrap

- Printed scrap

- Fiber scrap

- Roll scrap

- Loose film scrap

- Baled scrap